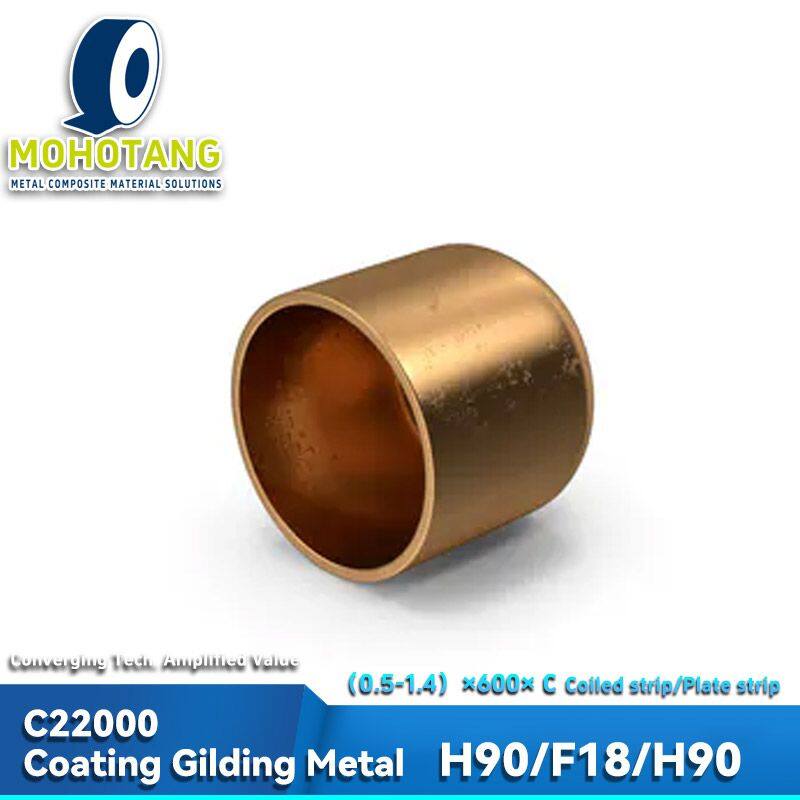

C22000 Coating Gilding Metal H90/F18/H90 Copper 3.1*139.5mm Brass 90 clad steel

Product Overview

The H90/F18/H90 copper-clad steel strip is a high-performance bimetal composite material with dual-sided H90 brass (C22000, Cu 88–91%, Zn balance) cladding on F18 deep-drawing steel substrate (C 0.11–0.19%, Mn 0.35–0.55%). With a thickness of 3.1mm, it combines copper’s conductivity/corrosion resistance and steel’s mechanical strength. Compliant with international standards (ASTM B152, IEC 61238) and Chinese GB/T 26015-201057.

Key Specifications

Mechanical Properties

Tensile Strength: 305–400 MPa (half-hard, annealed)

Elongation: ≥32%

Bendability: Enhanced post-annealing, suitable for multi-stage cold forming.

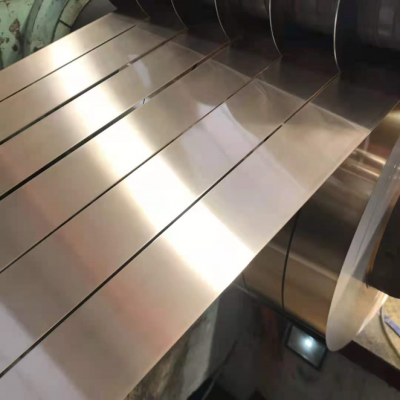

Geometric Tolerances

Thickness: 1.7-2.9,3.0,3.1,3.2,4.0mm (±0.08mm)

Width: 450–600mm (master coil), customizable slitting to 81–139.5mm

Clad Layer Thickness: 3.4–4% per side (total thickness), optimizing conductivity and corrosion resistance.

Chemical Composition

Substrate (F18 Steel): C≤0.19%, Mn 0.35–0.55%, Al 0.02–0.08%, S/P≤0.07%.

Cladding (H90 Brass): Cu 88–91%, Zn balance (C22000 compliant).

Process Advantages

Utilizes 8–12 precision steps: surface pretreatment→cold rolling bonding→intermediate annealing→precision thinning→diffusion heat treatment→inspection. Ensures interfacial bond strength of 31–40 kg/mm², certified by RoHS.

Applications

Electrical & Electronics: Terminal connectors, conductive shims (IEC 60947 compliant);

New Energy Vehicles: Battery connectors, EMI shielding components;

Industrial Manufacturing: Deep-drawn stamping parts (draw ratio≥2.5), electromagnetic shielding;

Power & Energy: Grounding materials (DL/T 1312-2023 compliant for Cu layer thickness & thermal stability).

Certifications

RoHS Directive (heavy metal restrictions);

Material COC and third-party test reports (SGS)